Issue 170 November - December 2025Please note: The issue content below is just a summary of the articles in the printed magazine.

The articles are not available on-line.

Please refer to the printed magazine for the complete article.

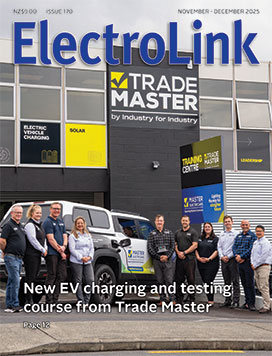

COVER STORY

New EV charging and testing course from Trade Master

Following on from the successful launch of its solar installation training, Trade Master is now launching a practical one-day course on how to test and maintain a commercial or residential EV charging station.

The course is designed for electricians who want practical guidance on how to ensure their installations are working optimally and are safe and documented correctly.

Trade Master’s head of training, Andreas Kasoulides, says from a wiring standpoint, installing a charging station is simply installing a switch between the car and a power supply. But it’s a control and safety switch, and there are a few things to get right in the set-up and commissioning as well as future maintenance.

“Our course will give you a practical understanding of how the charger communicates with the vehicle and sets the voltage and current limits. Once you grasp the basics of the ‘handshake’ and the control pilot, everything will fall into place because the smarts in the charging station take care of the charging operation. We will show you how to test and document this for your clients.

“We also address the safety functions and monitoring the charge to help you ensure installations continue to perform safely and well for your clients.”

Principal course designer and training lead, Raymond Tancrel, says in designing the course he has drawn from multiple sources, including the now-cited 2018 version of AS/NZS 3000 and amendments and the second edition of WorkSafe’s Electric Vehicle Charging Safety Guidelines and addendum.

Please refer to the printed magazine for the complete article

NEWS

Is the law failing to connect?

One of the biggest changes made to both the electrical safety regime and the electrical compliance regime in 2013 was the elevated focus on connecting installations to a power supply.

All safety risk management designed into the new regulations converged on this final bit of post-inspection prescribed electrical work that allowed permanent livening.

This connecting work now has its own set of regulated controls and can occur either side of the point of supply, depending on the sequence of work in connecting each installation. While its location is variable, the safety verification processes mandated in the Electricity (Safety) Regulations for connecting to a power supply are not. They cannot be overridden by commercial arrangements or by controls imposed by network companies.

Connection is defined in Regulation 73A (5) as the PEW “that is the final step that will allow electricity to flow in the installation or part installation on which other prescribed electrical work has been done”.

The criticality of the connection wiring, regardless of whether it occurs in a lines company’s works, a pillar, the hanging of a meter or anywhere else on the installation side, called for regulation that bound the connecter to the same set of safety procedures and their documentation, regardless of who the connecter is working for.

As a result, connecting fittings to a power supply is defined in the Electricity Regulations and not by a lines company nor by the EWRB. It is defined as its own unique form of prescribed electrical work (PEW) in Schedule 1, and the EWRB is then responsible for establishing classes of registration such as inspector, electrician, technician, engineer or line mechanic, along with competencies required for safely and lawfully connecting to a power supply. The Board then has to authorise via a licence, who may carry out the final connecting wiring step, regardless of any commercial arrangement or on whose property it occurs.

The EWRB has failed to do this. In its latest Gazette notice, the Board has ignored the unique electrical safety risks when connecting to a supply and has failed to set licence limits of work to authorise connection.

Please refer to the printed magazine for the complete article

NEWS

Industry asks Parliament to disallow new licensing regime

The failure of MBIE and its Electrical Worker Registration Board (EWRB) to consult effectively with the industry on changes to classes of registration and their limits of work has been met with strong criticism from industry organisations.

According to Master Electricians and the New Zealand Electrical Inspectors Association (NZEIA), this failure has been exacerbated by poor, evasive or no responses to questions and criticisms of the measures the Board has imposed by Gazette notices since 2023.

Frustrated with MBIE’s inadequate responses, these industry organisations have laid a complaint with the Regulations Review Committee.

This powerful parliamentary committee is there to scrutinise regulations and other legislative or disallowable instruments to rein in the power of the executive and government departments. The committee ensures that rules created by officials under delegation from Parliament do not stray outside the scope of the legislation that empowered them, and that elected and accountable members of Parliament and not officials remain in control of the content of the laws Parliament creates.

When the EWRB issues a notice under the Electricity Act, it is treated as secondary legislation and has the full force of law. If the industry cannot persuade officials to correct or withdraw a notice, a complaint to the Regulations Review Committee provides a nuclear option to have it removed by Parliament.

The industry complaint laid out five grounds within the committee’s standing orders to investigate complaints and showed how the changes the EWRB has made in implementing 41 classes of registration will not have the intended effect and are outside the scope of the Board’s powers.

Master Electricians and NZEIA have asked the committee to recommend to the House of Representatives that the House disallows the Board’s notices. The specific scope for the House to disallow notices was incorporated into the Act in 2021 following the introduction of the Secondary Legislation Act that year.

Please refer to the printed magazine for the complete article

AS/NZS 3000 proposed changes for 2027

Significant changes to the way buildings are wired are being planned for introduction in two years’ time. EL 001 standards executive committee member, Alec Knewstubb, provides insight into what he calls a paradigm change to the Wiring Rules.

By now you should be aware that an amendment to the Electricity (Safety) Regulations 2010 has, among other changes, updated Schedule 2 to recognise new standard editions. As a result, from 13 Nov 2025, we can choose to use the newly-cited 2018 edition of AS/NZS 3000.

The 2018 edition has a lot of changes from the 2007 edition we’ve been using for the last 15 years – ever since ESRs were first published in 2010. In fact, most of the Standards cited in the new Schedule 2 have been amended or revised. So designers, installers, inspectors will need to get their heads around all these changes. We have a year to get up to speed.

However, this article is not about those changes. Instead it’s about future changes, including the next edition of ‘3000’ which has been under way since early last year and is expected to be published in 2027. While there are a lot of changes in 2018 edition compared with 2007, most are incremental rather than radical.

Many of the changes in coming editions will be similar; providing clarification, or additional information, or closing off ‘loopholes’. That’s an ongoing process of improvement, and will continue. However, while such incremental tweaks will always be needed, they won’t be enough by themselves.

In order for ‘3000’ to be fit for purpose as the base standard for electrical installations in the next decade or more, there are also some significant issues that need to be addressed. The fundamentals of electrical theory don’t change, but the ways we use electricity do change, and new technologies emerge. Often such technologies come into use without sufficient attention being paid to ensuring they are used safely.

Until now, our Wiring Rules have been predominantly about one-way flow of LV AC from a grid supply, through an installation, to loads. And they have done, and will continue to do, a pretty good job of that. But rules for one-way flow of electricity are not good enough to cover the increasing complexities of modern installations. And we also need to consider whether the MEN earthing we have used for many years remains the best option in all cases.

Please refer to the printed magazine for the complete article

Understanding the basics of EV charging

Knowing how to test AC charging installations for electrical safety and how to simulate potential signal faults is key to verifying a charging station is functioning correctly. Glenn Inkster explains how testing is the only way to ensure reliable EV installations and fewer call-backs.

When you are ready to confirm whether an AC EV charging station is functioning correctly, relying on your basic multimeter is a great way to start.

- AC volts will confirm that there is power to the charging station, eliminating any issues with supply.

- DC volts will check that the charging station is generating the signal to communicate with the car.

Most of you will have access to a multimeter that can also measure frequency and the duty cycle of the control signal which can be used to confirm the current rate that the charging station is telling the car it can use. This signal is always present when there is power to the charging station, whether the charging station is plugged into the car or not.

Please refer to the printed magazine for the complete article

COVER STORY

Non-EX rated vehicles in hazardous areas

n April this year, the Government announced Health and Safety law reforms to reduce compliance costs and over-compliance when companies do what is reasonably practicable to meet their workplace safety duties.

But what happens when the Government itself forces companies to over-comply with the standards the government cites as mandatory for compliance with the Health and Safety at Work (General Workplace Risk and Management) Regulations.

Hazardous area inspector, Garry House, says rulings by WorkSafe NZ inspectors with only a partial understanding of cited standards are causing industrial companies to spend time and money managing risks in excess of the safety requirements set by world experts through the international standards process.

House is not just a hazardous area inspector, he is also a chair or member of multiple joint standards committees that develop the standards for hazardous areas in New Zealand and Australia. He says the productivity of local manufacturers is being eroded by poorly informed enforcement decisions by WorkSafe inspectors who frequently know less about ensuring electrical safety in hazardous zones than the companies responsible for managing them.

He points to the guidance published by WorkSafe on operating a forklift in a hazardous area which states that PCBUs have a duty to “minimise the risk of the associated ignition sources in accordance with the hierarchy of controls, with the goal of applying the highest possible standard of protection”.

WorkSafe says in its High Hazards Newsletter in February: “the use of standard forklifts in parallel with portable gas detection, without any engineering standards and controls applied to the forklift itself, is a lower order control approach that will need to be improved upon in most, if not all, circumstances”.

WorkSafe then advises that battery electric forklifts ‘certified’ for use in hazardous areas are available to achieve the higher level of control WorkSafe expects, and that “there are standards that can be applied to manage ignition risks arising from internal combustion powered units”.

Garry House says this advice is currently driving over-compliance by WorkSafe, where the solutions that the workplace regulator is demanding are in excess of the standards WorkSafe cites for the purpose of controls.

Please refer to the printed magazine for the complete article

New rules to simplify machine guarding and dust exposure

The way machine guarding is regulated and how wood dust in timber processing and flour dust in bakeries is addressed in workplace exposure standards are now being reviewed by WorkSafe.

The objective is to provide clearer and easy-to-implement rules that don’t compromise safety, says Workplace Relations and Safety Minister Brooke van Velden.

WorkSafe is now consulting with manufacturers, including wood processors, bakers, and millers, to help businesses focus on managing genuine risks rather than navigating red tape.

“We’re simplifying machine guarding rules and reviewing exposure standards to reduce complexity and improve consistency in the manufacturing sector,” says van Velden.

The proposed changes aim to ensure standards reflect real-world risks and align with international benchmarks. Manufacturers have said that the current rules are unclear and difficult to apply, leading to unnecessary costs and compliance burden.

Adding to this burden is the inconsistent way WorkSafe implements the rules. Van Velden says a business owner told her they got conflicting advice from WorkSafe inspectors on identical machine guarding in Auckland and Christchurch that deemed the same machine guarding to be compliant in one city but non-compliant in the other.

“During my nationwide consultation and roadshow, businesses described the law as full of grey areas, with outdated guidance that creates confusion and unnecessary cost. We’re acting on that feedback, with changes designed to address the specific pain points raised.”

Please refer to the printed magazine for the complete article

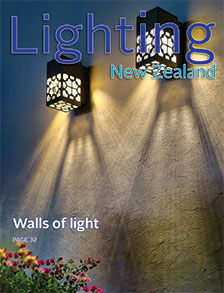

COVER STORY

Walls of light

For such an apparently simple task, a well-lit wall can be one of the most rewarding visual endeavours for a good lighting practitioner. It can be rewarding in two ways: by applying exemplary lighting techniques to enhance a space, or by creating an aesthetically appealing result, or even by achieving both at the same time.

Wall lighting can be divided into two main categories, that of exterior and interior spaces. While both have their own set of challenges and requirements, the basic lighting techniques remain the same, whereas the availability of luminaire selections and varying functional requirements lead to the application of different approaches.

Interior wall lighting traditionally has several specific aims. These range from lighting specific subjects like artworks that are mounted on the wall, through to helping to create a spatial feel by clever use of light to enhance or downplay aspects of physical size or add an extra feel of illuminance to a space.

Interior lighting generally has less restriction on luminaire selection or placement, as the physical containment has a wider range of mounting options, from suspended luminaires through to utilising walls, ceilings and floors to install either recessed or surface mount luminaires.

At its most basic effect, wall lighting can provide clues to orientation, as the eye will be drawn to the brightest surface, therefore allowing the brain to instantly assimilate the architectural layout and direction of flow through a space. Accentuated walls can help us to differentiate between functional areas and spatial transitions, often evidenced by creating recognisable entrance and exit zones as well as inviting users towards common spaces.

Tricks of light can be implemented with wall lighting to transform a space by using a high level of uniformity to expand perceived room size, downplay or enhance vaulted or high ceilings, and limit the constrictive feel of narrow environments.

Please refer to the printed magazine for the complete article

Luminaire maintenance and cleaning

If the lights are on, then we believe they are performing at their optimum level, if we even think about them at all. It is only when the lights go out that anyone really pays attention to them and even then, the chances are they get ignored until there are multiple failures that make an area completely unserviceable.

If we treated any of our other services or assets in this manner, especially ones so critical to our daily well-being, it would be considered irresponsible. Why is it that lighting maintenance is such an underrated and underperformed task?

Lighting ‘nerds’ may have their eye drawn to luminaire irregularities, such as discoloured panels, spotlights that are misaimed, or fittings that have evidential marks from overheating or have gone completely dark, but everyone else seems to just walk on by. There are more reasons we should be concerned with luminaire maintenance and cleaning other than just combatting the darkness.

Originally when luminaires had replaceable lamps, such as fluorescent tubes, discharge lamps or incandescent and halogen lamps, the luminaires tended to get a bit of a dust off when the lamps were replaced. Stores even had maintenance schedules to perform re-lamping of entire sections. Now with integrated LED luminaires, these schedules have regularly been obsoleted, indeed this maintenance reduction cost was often a selling point of those trying to transition clients to an LED upgrade.

Users tend to think of LED luminaires as set and forget, only paying attention to them when they have a catastrophic failure, even tending to choose to ignore them when they have an obvious parametric failure, like the physically evident discolouration of a diffuser.

Apart from replacing expired luminaires, cleaning a luminaire is the next best piece of maintenance that can be performed and has more advantages than just the obvious light increases from dust removal.

Please refer to the printed magazine for the complete article

|