Issue 158 November - December 2023Please note: The issue content below is just a summary of the articles in the printed magazine.

The articles are not available on-line.

Please refer to the printed magazine for the complete article.

COVER STORY

Securing safety automation with Pilz

Just as it has been obvious for many years that productivity cannot advance without automation and that automation cannot advance without safety, it is now becoming just as obvious that productivity, automation and safety together can no longer advance reliably without security.

As production techniques and industrial plants becoming more interconnected through information technology, it has become easier for attackers to hack into automation and control systems. Without effective security on every level, intruders can manipulate these systems and compromise the safety of operators using machinery.

With every manufacturer and industrial company in New Zealand required to do what is reasonably practicable to ensure the safety of people using plant, questions are being asked about the practicability of applying security to automated safety solutions.

One international automation technology company, Pilz, is stepping up to not just provide answers but also the training needed to help industrial companies work out what they really need to protect their people, plant and production.

Thomas Pilz, the managing partner of Pilz, was in New Zealand in October to introduce the work the company is doing on securing industrial plant against both intentional and unintentional faults, along with celebrating the companies 75th anniversary with the Pilz New Zealand team.

He said security used to be the exclusive domain of information technology experts in the form of IT security, but a much broader approach is needed today to make manufacturing safe and secure.

Please refer to the printed magazine for the complete article

NEWS

New registration classes causing confusion

What was once four classes of electrical registration has now ballooned out to 41 classes following the Gazette notice issued by the registrar of the Electrical Workers Registration Board on September 1.

The Board has added to the original four classes over the last 13 years and driving the latest additions is the Board’s recognition that there are electrical work risks it should manage that require a higher level of competence to be endorsed than the Board believed was necessary for the registration and licence classes it had.

The new endorsed registration classes are the Board’s response to the work risk levels introduced in the 2012 amendment to the Electricity Regulations. The high-risk areas of prescribed electrical work (PEW) have provided a benchmark for the Board to set competencies appropriate for people doing this high-risk work or inspecting it.

The way the Board has gone about addressing these risks has caused a lot of confusion and the Board has yet to lay out any training pathways for registered people to gain the competencies required to continue doing this work after the designated changeover dates to the new licensing regime.

Please refer to the printed magazine for the complete article

NEWS

Alternative ways to cite standards

The 2010 Electricity Regulations were designed to have annual updates to cite new editions of standards and their amendments in the regulation schedules, but no recent government has had sufficient interest in the safety of the public to amend the Regulations since 2014 when it amended the citation of just one standard.

The government’s continuing refusal to recognise new and updated standards was addressed in the September issue of ElectroLink (See page 8 ‘Standards citation – is there a better way?') This article identified alternative means of freeing the standards citation logjam.

The logjam has occurred only because successive governments haven’t done their job, not because of a design failure in the standards approval process. It therefore follows that the suggested alternative pathways would remove the cabinet from the process and replace it with a simple sign-off by the relevant minister. This article is in response to calls to ElectroLink requesting more information on how potential changes could occur.

As it stands today, the government continues to demand control of the citation of each standard but refuses to exercise that control responsibly and provide the industry with the protection from liability it needs to take up the new versions.

The problem is that the lengthy process of citing new standards requires the government to create an amendment to the Regulations and that requires a cabinet decision.

Please refer to the printed magazine for the complete article

Will engineer registration shut inspectors out of project work?

Electrical inspector, Tony Doyle, looks at how the proposed occupational regulatory regime for professional engineers could impact electrical work carried out by electricians and inspectors

Significant changes are on the horizon for electrical engineers as they move towards the prospect of being registered and licensed. In contrast, electricians have long been living with registration and, for the last three decades, have been required to have a licence to carry out prescribed electrical work.

The proposed legislative changes to engineering registration and licensing bring to the forefront the critical need to address the issue of regulatory overlap with other professions, particularly electricians, whose work frequently intersects with that of engineers. This challenge necessitates a thoughtful approach to harmonize regulations, a concept that, while seemingly straightforward in theory, may prove difficult to execute in practice.

The uncertain landscape of regulatory reforms for electrical workers and engineers raises a compelling question: what lies ahead for where these two professions meet? This crucial space, as represented in Figure 1, is where electricians engage in the intricate task of making design and engineering decisions. It could also be argued that this space is where the high-risk electrical work design and certification decisions are located. It stands at the crossroads of two vital domains, each playing an essential role in ensuring the safety and efficiency of electrical systems.

Please refer to the printed magazine for the complete article

COVER STORY

Some key strategies for preventing cyberattacks

Our world is becoming ever more data centric and our reliance on computers is ever more entrenched. But for modern day computing to be effective, it needs to connect, and this invariably means accessing the internet, that is cyberspace. The world economy now cannot function without the internet, nor can critical infrastructure.

But it seems cybercrime is almost daily news. The same internet we need to conduct our business is also the very tool hackers use to infiltrate our businesses. Security breaches are occurring more frequently and are not only highly embarrassing for the companies involved, but also result in large claims for compensation and lost business.

Cybercriminals look to gain advantage from industry, usually financial, by stealing valuable data, such as customer databases and intellectual property and either selling it or asking for a ransom for its return. They also create malicious software or malware that disrupts or stops computer systems altogether until a ransom is paid.

Keeping companies free from cyberthreats is arguably the biggest challenge confronting businesses right now. But what can reasonably be done to keep your company safe? What steps can be taken to secure your data and prevent these cybercrimes?

It’s important to accept that the battle against cybercrime is not a one off event; it’s going to be an on going war, where there is no finishing line. The motivation for cybercrime remains high while affected companies continue to pay exorbitant ransoms.

Paying a ransom is often seen as an easier and much faster resolution than negotiation and a more cost-effective solution.

However, the payment of ransoms undoubtedly stokes cybercriminals. This is why many governments around the world, including New Zealand, strongly advise against making any such payments.

Please refer to the printed magazine for the complete article

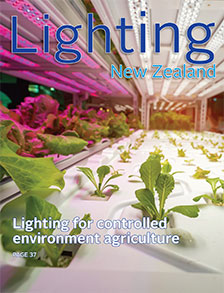

COVER STORY

Lighting for controlled environment agriculture

As the world enters times of increasing food insecurity, can the lighting industry step up and become a source of hope for the future. It is such a multi-faceted question, but the short answer is yes, there is a definite potential for lighting to play a role helping to meet our global food needs.

Often in New Zealand, our first thoughts of the use of horticultural lighting refer to grow lights, and their murky history in the growing of cannabis. De-stigmatising grow lights from illegal operations and shady suppliers is not peculiar to New Zealand, but in other parts of the world, the use of commercial lighting for grow lights has been widely practised, especially in countries that have low winter sunlight hours or harsh exterior climates. In the U.S and many parts of the world, the decriminalisation of cannabis as well as a bourgeoning industry of medicinal cannabis have driven an upswing of interest in the indoor horticulture lighting industry.

Controlled environment agriculture is where technology is utilised to augment or replace traditional food production methodologies. It can include everything from greenhouses, vertical farms and aquaculture to complete plant factories.

Many components of traditional farming are replaced, from the soil to nutrient sources and pest control, but the aspect that is of most import to the lighting industry is that of replicating, or even enhancing the role of sunlight. The electrical industry has a major stake in the industry, as it involves multiple layers of requirements, from HVAC through to control systems and increased electricity supply.

Please refer to the printed magazine for the complete article

Downlights 101

One of the most ubiquitous luminaires in the lighting arsenal is the downlight. They can be found in most recent builds, from residential through to commercial and industrial. Downlights have had many iterations, from utilising original filament lamps, reflector lamps and halogen lamps, through to breaking into LED replacement lamps and finally the integrated LED options commonly found today.

Other than the light source, the actual downlight has pretty much stayed the same, a simple luminaire designed to fit flush or recessed into the ceiling, with some extra options, for example, gimbal or tilting functions and upgraded ingress protection.

Their popularity is down to many aspects, including their ease of installation for contractors, an aesthetic suitable for almost any location and pricing structure to match all budgets, from the expensive architectural luminaires, down to extremely economic bulk manufactured items.

In this article we will take a closer look at some ways to make the most of your downlight installations, with some tricks and an overview of the permutations available and how they can affect their suitability for an install.

Please refer to the printed magazine for the complete article

|